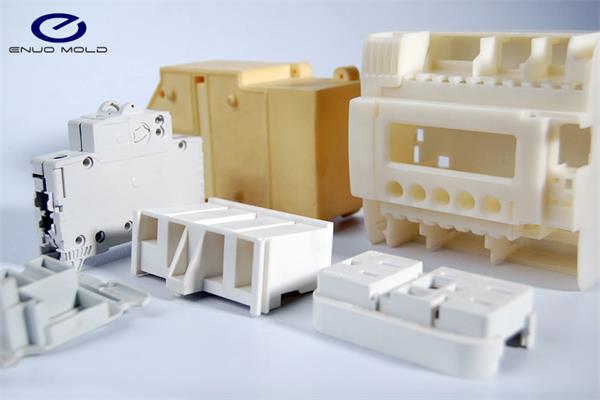

Dongguan Enuo mold Co.,Ltd is a subsidiary of Hong Kong BHD Group, the core business is injection mold manufacturing and injection molding.Furthermore, Enuo mold is also an OEM factory engaged in inspection fixture/Gauge R&D,Die casting, CNC machining,Prototype products R&D,Parts spraying and assembly.

© Copyright 2021

DONGGUAN ENUO MOLD CO., LTD

Hot Products - Sitemap

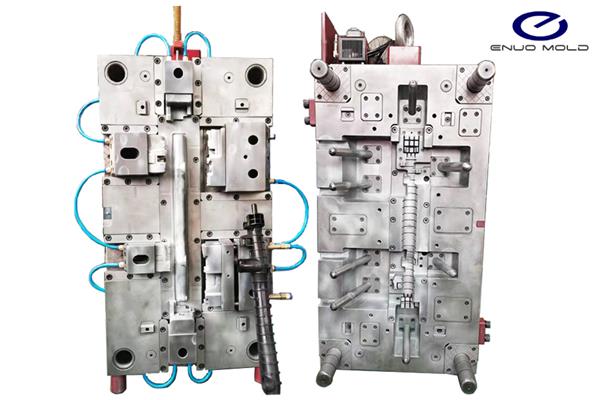

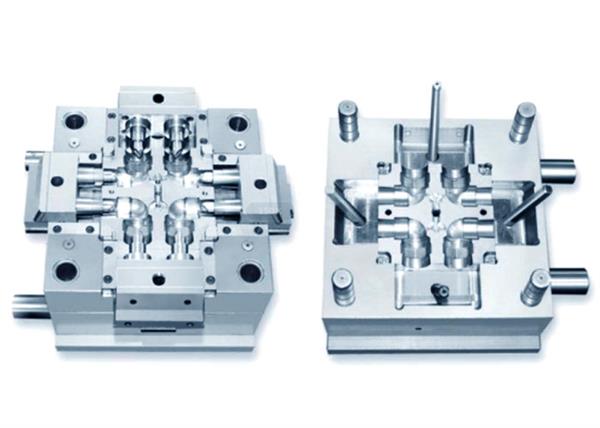

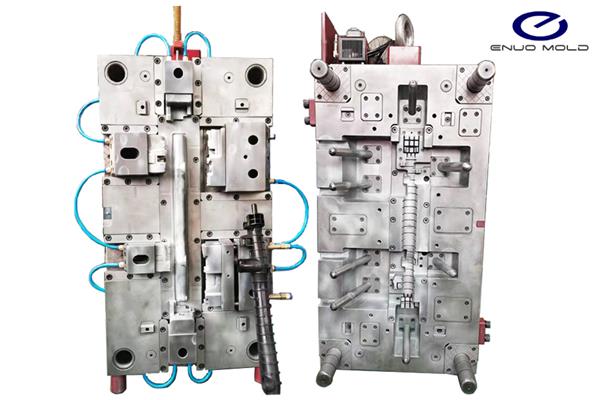

Injection Mold,

Plastic mold,

Thermoplastic Mold and Radiator Plastic Tank Mould,

Radiator Plastic Tank Mould,

Automotive Parts,

Motorcycle Parts,

Medical part