We provide fantastic energy in top quality and advancement,merchandising,gross sales and marketing and operation for Toothbrush Mold, Unscrewing Mold, Plug, Plastic Container,China Tooling. If you are interested within our products and solutions, you should come to feel absolutely free to ship us your inquiry. We sincerely hope to ascertain win-win company relationships with you. The product will supply to all over the world, such as Europe, America, Australia,Albania, Montpellier,Bangalore, Nepal.Merchandise have been exported to Asia, Mid-east,European and Germany market. Our company has constantly been able to update the items performance and safety to meet the markets and strive to be top A on stable quality and sincere service. If you have the honor to do business with our company. we'll undoubtedly do our very best to support your business in China.

© Copyright 2021

DONGGUAN ENUO MOLD CO., LTD

Hot Products - Sitemap

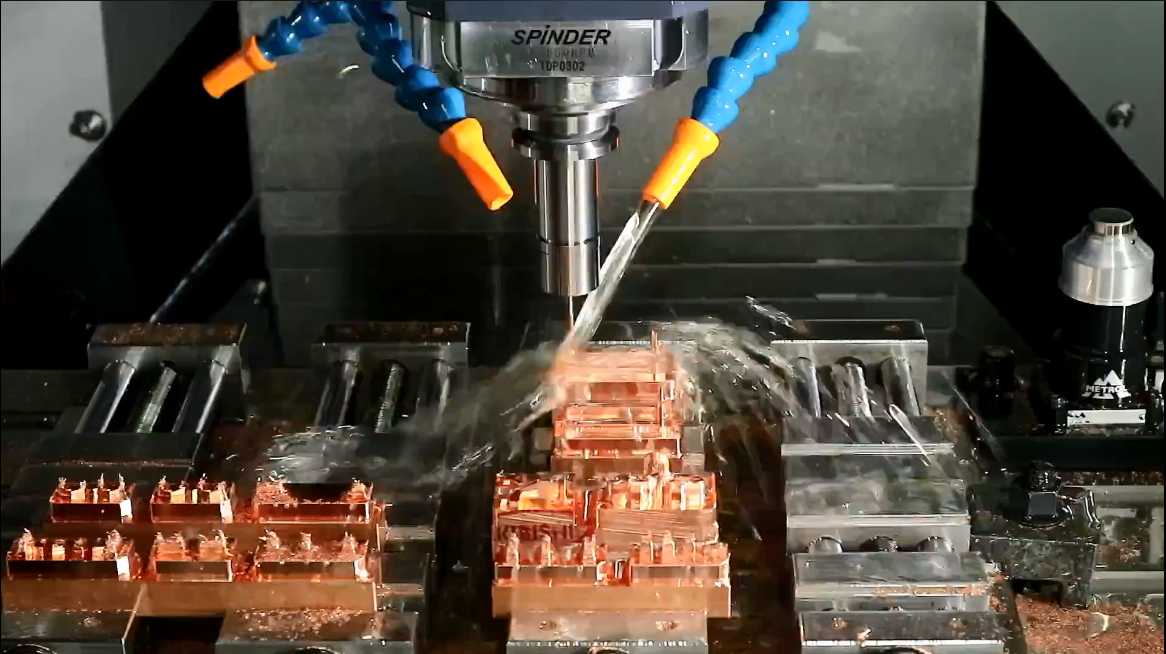

Injection Mold,

Plastic mold,

Thermoplastic Mold and Radiator Plastic Tank Mould,

Radiator Plastic Tank Mould,

Automotive Parts,

Motorcycle Parts,

Medical part