HaHa, for a man who have engaged in mold industry for 8 years, i have a lot to “complain”, and the first one is: Too few girls around us… Yeh, just made a joke, but too tell the truth tooling workshop work may really not suitable for beauties. as too much work there are heaven, not clean and sense of space needed. As you can see from below picture, these are new projects (two similar molds) we shipped to customer on May 26th, 2017, this is why our marketing specialist who appears at above picture is so happy, Lol…

Mold size: 1650*1595*1026, and weight 13 ton.

Ok, so next, if you have spare time, please follow me to know the magic journey-how the part drawings become a machine(mold). like all the molds we made before.

Step 1: Customer placed the order with part data.

Receiving the part “2D/3D data”, “injection machine size” and “part material parameter” etc.

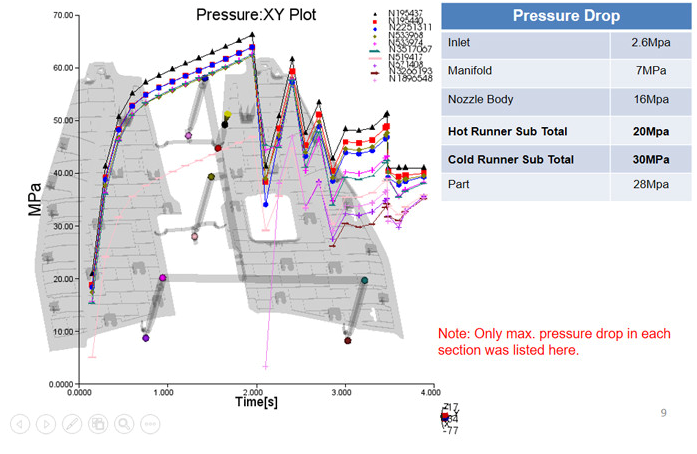

Step 2: Mold-flow and DFM report

Doing the mold flow analysis, according to analysis result to do the DFM report. Communicated with customer to determinate the mold design proposal.

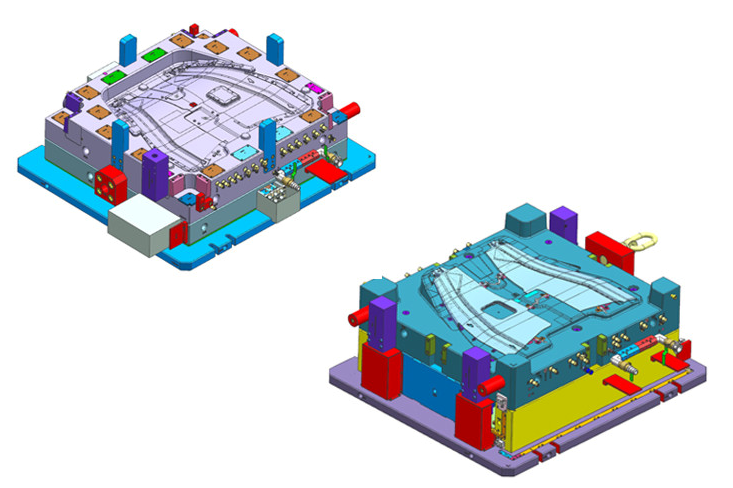

Step 3: Mold designing Our mold designers will complete the design according to the mold flow and DFM report. Then submit the design to customer for validation.

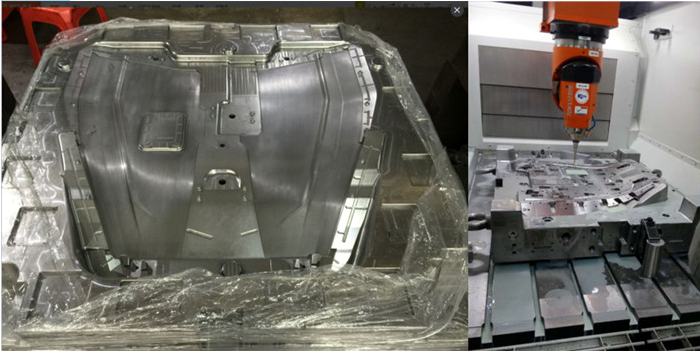

Step 4: Mold manufacture and assembly

After getting the customer approval about the finally mold design, we start to steel machining and parts assembly.

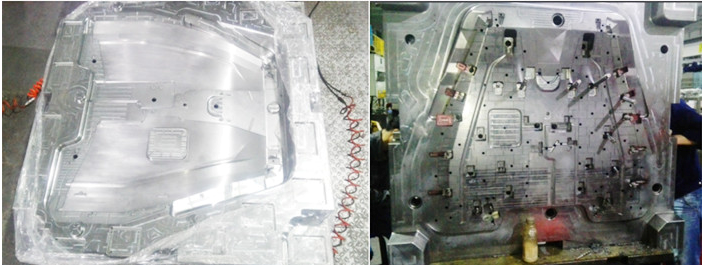

Step 5: Mold trial

Mold trial is the most important process to inspect the mold manufacture quality, try to best to explode the mold issues then solve it in our plant, ensuring the mold could be produced well at customers’ injection plant.

Step 6: Mold optimizing.

According to the mold trial result, we will do the mold improvement work to optimize the mold problems. Normally we will have the mold tested 1-3 times to get the mold completely reach customer requirement.

Step 7: Shipment.

After getting the customer approval for mold shipment, we would package the mold well then contact the logistic forwarder to deliver the mold to customer.

So, once you want to know more story about our team, please contact by: harry@enuomold.com

Post time: Sep-14-2020