1. The purpose of the mold trial?

Most of molded defects are happened during the product plasticizing and molding process, but sometimes related to the unreasonable mold design, including the quantity of cavities; the design of the cold / hot runner system; the type, position and size of injection gate, as well as the structure of the product geometry itself.

In addition, during the actual test process, in order to make up the lack of mold design, the testing staff may set an incorrect parameter, but the actual data range of mass production required by the customer is very limited, once the parameter settings with any slight deviation, the quality of mass production may lead to far beyond the allowable toleration range, it will result to actual production yield be declining,cost rising.

The purpose of the mold trial is to find the optimal process parameters and mold design. In this way, even the material, machine parameter or environmental factors have something change, the mold is still able to keep stable and mass production uninterruptedly.

2. Mold trial Steps we are following.

To ensure the mold trial result correct, our team will obey below steps.

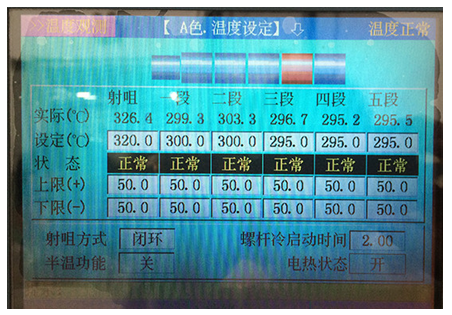

Step1. Setting the injection machine “nozzle barrel ” temperature.

It should be noted that the initial barrel temperature setting must be based on the material supplier’s recommendation. And then according to the specific production conditions for appropriate fine-tuning.

In addition, the actual temperature of the melt material in the barrel should be measured with a detector to ensure compliance with the screen shown. (We have had two cases which two temperature difference up to 30 ℃).

Step 2. Setting the mold temperature.

Likewise, the initial temperature setting of the mold must also be based on the recommended value provided by the material supplier. Therefore, before the formal test, the temperature of the cavities surface must be measured and recorded. Measurement should be done at different location to see whether the temperature is balanced, and record the corresponding results for the follow-up mold optimization reference.

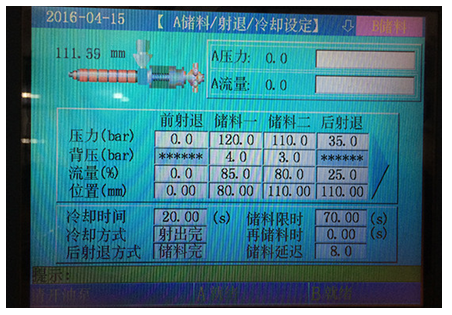

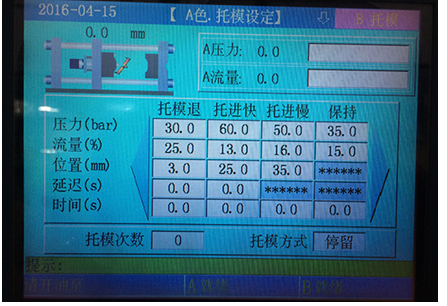

Step 3. Setting the parameters.

Such as plasticization, injection pressure, injection speed, cooling time, and screw speed according to experience, then optimize it appropriately.

Step 4. Finding the “injection-holding” transition point during filling test.

The transition point is the switching point from the injection stage to the pressure holding phase, which can be the injection screw position, the filling time and the filling pressure. This is one of the most important and basic parameters in the injection molding process. In the actual filling test, the following points need to be followed:

- The holding pressure and holding time during the test are usually be set to zero;

- Generally, the product is filled to 90% to 98%, depending on the specific circumstances of the wall thickness and mold structure design;

- Since the injection speed affects the position of the pressing point, it is necessary to re-confirm the pressing point each time when the injection speed is changed.

During the filling stage, we can see how the material filling in the mold, thus judging which positions easy to have air trap.

Step 5. Locate the limit of actual injection pressure.

The injection pressure setting on the screen is the limit of the actual injection pressure, so it should be set always greater than the actual pressure. If it is too low and then be approached or exceeded by the actual injection pressure, the actual injection speed will automatically decrease due to the power limitation, which will affect the injection time and the molding cycle.

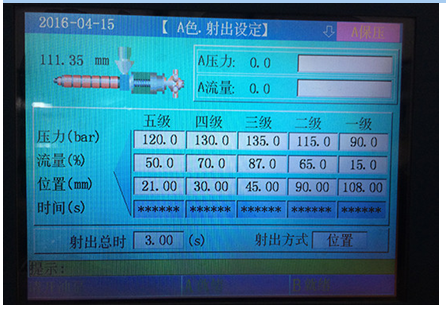

Step 6. Find the best injection speed.

The injection speed referred to herein is the speed which filling time is as short as possible and the filling pressure is as small as possible. In this process, the following points need to be noted:

- Most products surface defects, especially close to the gate, are caused by the injection speed.

- Multi-stage injection only be used when a single stage injection can not meet the needs, especially in the mold trial.;

- If the mold status is good, the pressure setting value is correct, and the injection speed is enough, there product flash defect is no directly relation to the injection speed.

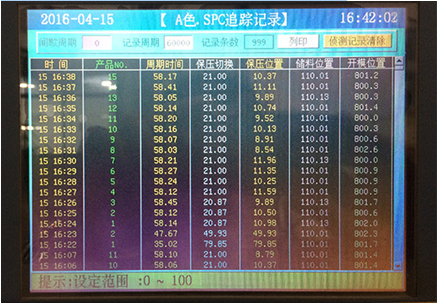

Step 7. Optimize the holding time.

The holding time also be called as injection gate solid time. In general, the time can be determined by weighing. resulting in different holding time, and the optimum holding time is the time when the mold weight is maximized.

Step 8. Optimizing other parameters.

Such as holding pressure and clamping force.

Thanks very much for your time to read here.know more about mold trial

Post time: Jul-25-2020